our location

1340 Reynolds Ave #120, Irvine, CA 92614, USA

Applicational uses

CETY’s heat-to-power installations are versatile, fitting a broad spectrum of heat recovery applications including industrial facilities, power plants, biomass boilers, turbine and engine compression stations and more.

Up to 140kW

reliable, base-load

electricity production

Heat Recovery Solutions

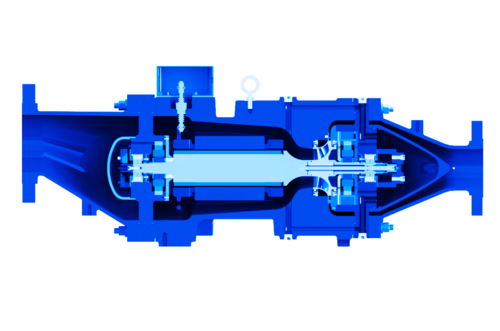

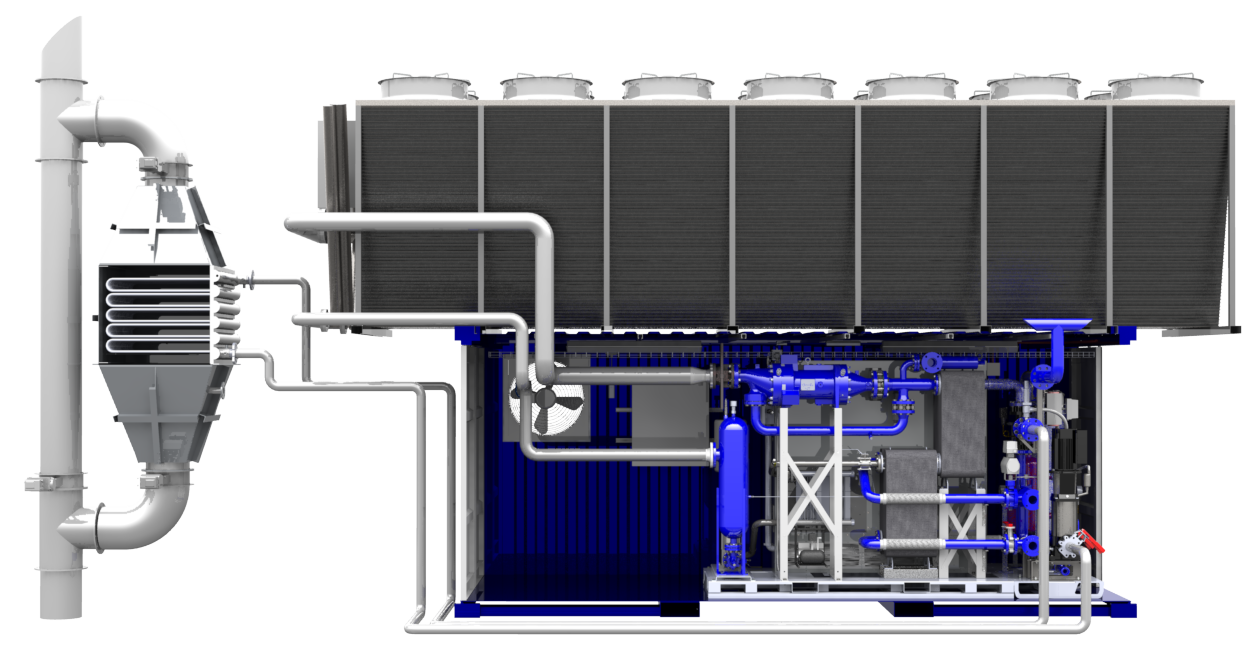

Since the mid 2000s, HRS has been designing and building ORC based systems to convert wasted heat into usable electric power. We used advanced magnetic bearings, high speed power electronics and compact self-cooling permanent magnet generators to bring cost effective solutions to the small industrial market. The Clean Cycle I (CCI) with 125 kW gross power rating was installed over 100 times and produced > 1,000,000 MWh. Many continue to run today.

Then we developed the Clean Cycle II (CCII) with 140 kW gross power rating. Still based on the core technologies, but with increased standardization and optimized packaging. This reduced application specific design work and minimized installation requirements. Allowing access to medium temperature sources of steam, flue gas, cooling thermal oils and pressurized hot water systems.

Today we continue to develop the CCII and install heat recovery solutions around the world with operating units in the Americas, Europe, and Asia. We have also partnered with a great company to bring productive heat recovery to larger situations, allowing us to provide cost competitive solutions for applications with heat flows from 750 – 10,000 kWth.

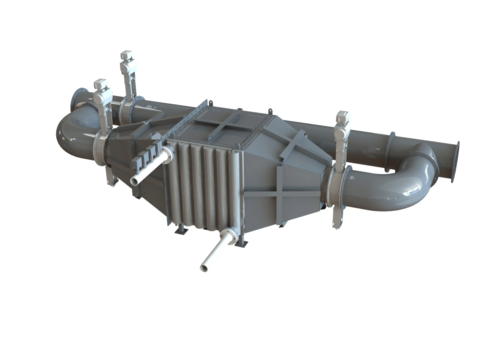

Waste Heat Recovery Components

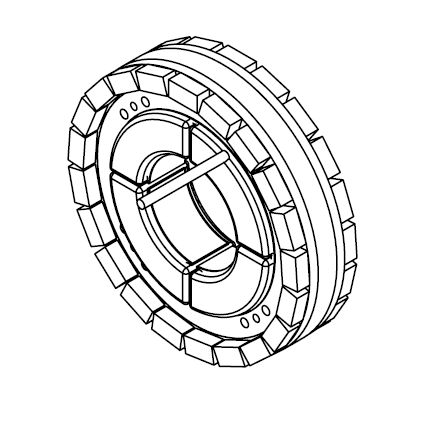

o Heart of the CCII

o Hermetically sealed

o Permanent magnet generator

o High speed expander

o Low maintenance

o No rotating seal

o No oil lubricant

o No gearbox

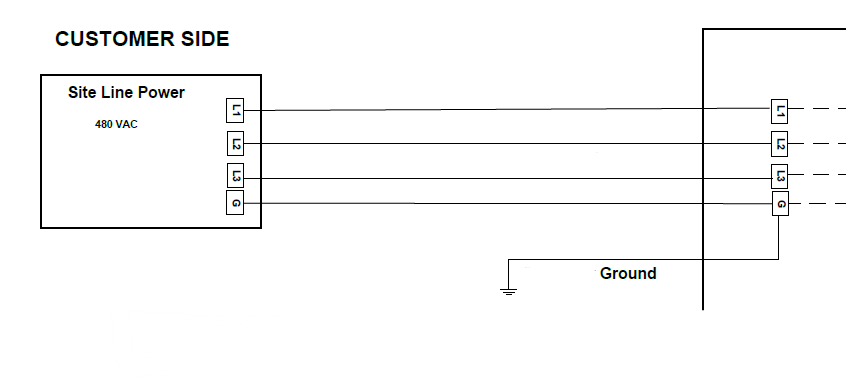

o AC/DC/AC power electronics

o Power Factor Selectable between 0.9 and 1.1

o 3 phase 480 V

o Standardized and Modular

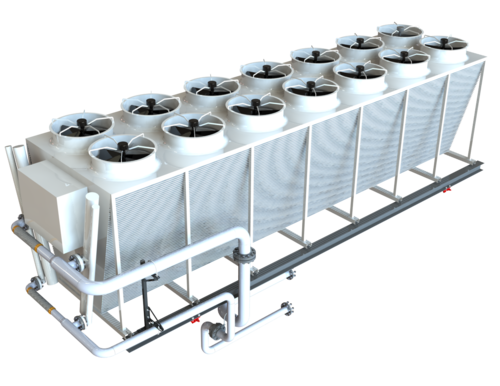

o Air blast Condenser with microchannel technology

o Plate frame heat exchangers

o Custom sizing

o Standard process diagram

o Variable fuel source adaptable

o Modular installation

o Autonomous Control

o Adaptable/ Movable Design

Product Details

| CCII | Custom Solutions | ||

|---|---|---|---|

| Heat Source | Available Energy (kW) | 700 – 4,000 | 3,000 – 10,000 |

| Flue Gas | Supply Range (C) | 300 – 500 | 250 – 600+ |

| Flue Gas | Return Range (C) | ~150 – 200 | ~180 – 250 |

| Steam | Supply Range (C) | 140 – 200 | |

| Steam | Return Range (C) | Condensate | Condensate |

| Pressurized Water | Supply Range (C) | 145 – 165 | 250 - 350 |

| Pressurized Water | Return Range (C) | ~120 – 130 | |

| Thermal Oil | Supply Range (C) | 145 – 165 | 250 - 350 |

| Thermal Oil | Return Range (C) | ~125 – 135 | |

| Cooling Sink | Caloric Rejection (kW) | 600 – 3,500 | 2,300 – 7,500 |

| Ambient Air Condenser | Air Temperature (C) | < 45 (derate > 35) | < 45 |

| Water Condenser | Supply Temperature (C) | 10 – 40 (derate > 35) | 10 – 85 |

| Water Condenser | Return Temperature (C) | ~20 – 50 | 30 – 95 |

| Download | Brochure | Brochure |